A printing company is one of the best businesses to be selected. Why do I think so? Because of my findings so far, although the days of the printing company to build more and more, customers or the market is also growing, so it is an income opportunity is very large.

Let’s see to have, wherever and wherever we direct the view, certainly almost all of the products or goods as a result of the printing press will always exist, for example: books, notes/invoices which we used to get while you shop in stores or markets, receipts, the containers of food appearance or appearance other items, bag (handbag/shopping bag), cards, invites cards, schedules, hang tag or label, letterhead, covers, decals, paper prints, ID cards, catalogs, pamphlets, company profiles, publications, programs, tabloids, banner ads, advertisements and so forth.

Offset printing has entered into an era with its main concentrate of attracting little companies and providing quick manufacturing job convert around with high quality. With the customization and variety of job-specific orders, the quick printing market, using the latest technologies, has outpaced the offset printing market in the area of producing the high-quality printing, using appropriate promotion, with a concentrate on the little company goals and objectives.

Offset printing outlets are finding their way to achievements by giving their customers not only quality printing, but also using customization, providing their customers and end customers with variable programs. This implies written text and graphics can be streamlined and created to fit the needs of many in a personal way. For instance, if you have a manufacturing run of 1000 printed out catalogs, digital printing can change the style, written text, format, and the information on each sheet in a single pass, thereby customizing each printed brochure. The key here is using appropriate promotion and customization to grab the end users' interest. This is one very essential strategic benefit to the little company client, providing speed, accuracy, and customization, grouped with appropriate promotion at a price over the popular offset printing procedure.

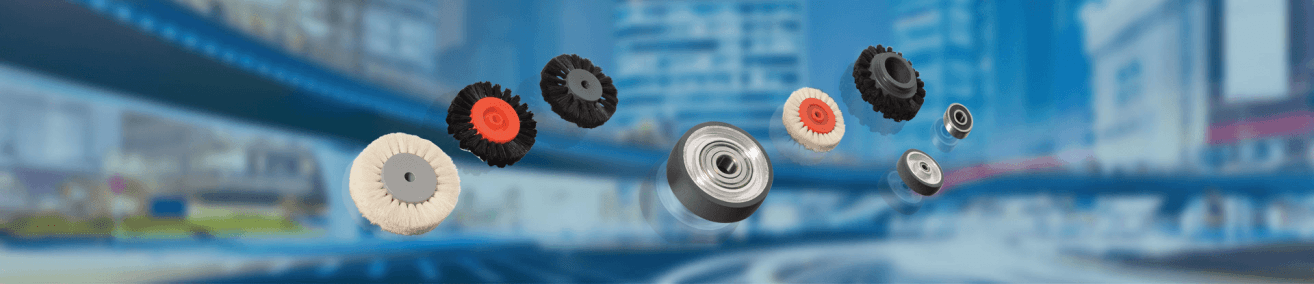

With more printing customers seeking to lower their promotion budget, it seems sensible to have their materials created an affordable and timely manner. It is essential to keep advertising costs down with affordable Screen Printing Platen and Offset Printing Supplies. Therefore, little companies are moving toward the one stop shop convenience of digital printing where time constraints and quick turnaround are essential in a quick moving appropriate promotion atmosphere.

In today's world, where quick response is essential to appropriate market needs, digital printing and its array of positive attributes lend its achievements to the ever ending ideas of future programs. The trend in pricing is decreasing per printed out impact, which makes it the most attractive and what you want for the price conscious customer. The need for printing is ever rising, as more organizations are coming forward. And in the race to excel, Printing Equipment For Sale has become a necessary weapon for them. And offset technique provides them with nothing but the best. This printing method has become the base for the achievements of every organization.