Ink is one of the greatest inventions of science and technology. Can you imagine the amount of burden ink has reduced after its invention? If I take you back to ancient times where there was no ink at all, could you be able to carry books that are made of stone? People used heavy things to imprint their messages on. At one point, it became impossible to carry these heavy materials to places it was needed due to carrying a cost and also for the fear of a message getting damaged on way. Printing Ink has indeed bought an end from this pain of heavy messages being engraved.

There were times when ink was made by crushing berries, using bulk of trees, plants and even minerals. Different culture had different ways of conveying a message. There were cave drawings that were carved in walls of caves by the early man. As Greeks used stylus, that was made up of ivory, bone and metal to make marks on waxed tablets. Many ancient cultures had their own techniques to make colours and inks for their usages. But the first to invent ink was the Chinese, which they used for commercial usages later it was developed and adopted by others too.

Ink can be defined as combination of dyes, solvents, pigments, resins, surfactants and solubilizers, etc. As the ink developed with time so did the paper and Printing ink is that ink that is basically used to print on papers through various machines. It contains colorant and a liquid to hold the colour and unite it with the paper. The thickness of the ink depends on its usage. Ink used for writing is thinner than the ink used for printing that is greasier. It is designed in a manner to be able to work with explicit kinds of equipments and machineries to print so that it produces a clear image without building up in the machinery. Always try to get the inks as per your requirement, and that are friendly to your machine and from a good, trusted dealer. Otherwise, you will never get the result you need and expect.

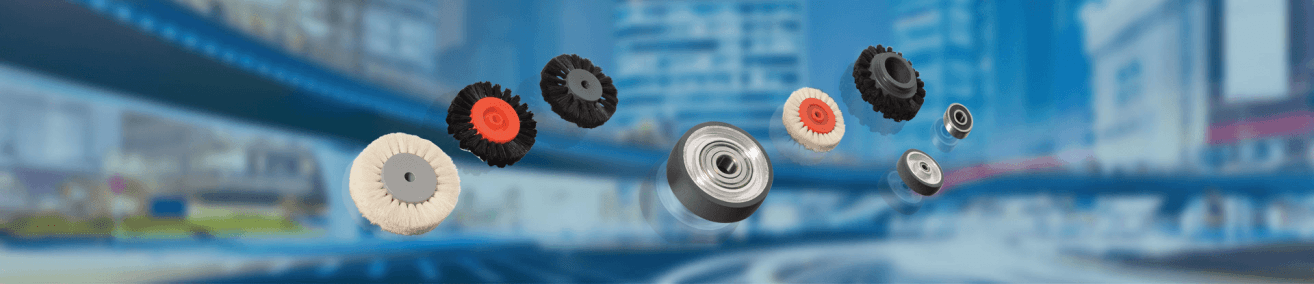

While we talk about commercial printing Rubber rollers are too an important factor to create good prints. The rubber rollers first receive the ink before transferring them to the plates. A good dealer or a printing press will have rollers that use CNC. Rollers grooved–complex patterns those are tapered and crowned–parabolic. Durometer & surface- finish is according to customer condition. The rollers should meet the customer needs and requirements with the highest quality maintained. One needs to mix the compounds well to get desired result.

Rubber rollers play an important role in the printing process, so if you are a printing house make sure to get proper machineries from a trusted dealer. And if you are trying to find good printing house then do make sure that they know their work well and provides you with maximum benefit at your comfort.